Antistatic PVC Floor

Antistatic PVC Floor

1.Permanent and consistent anti-static function with ESD

(Electro-Static discharge) Technology

2.Highly stain resistant and outstanding wear resistance with

UV Coating surface,make for Lower maintenance cost

3.Excellent in Fire prevention ,moisture proof and anti-corrosion

4.Uniform size and Multiple options in color with Fade Resistant

5 Prominent installation performance and workability

6.Low outgassing emission and dust-free technology

Details

Antistatic PVC Floor

Technical Data

Item | Technical Data | |

THICKNESS EN428 | 2.0 mm,2.5mm,3.0mm | |

SIZE EN426 | 600×600mm | 610×610mm |

WEIGHT EN430 | 3.8kg/2.0mm,4.8kg/2.5mm,5.8kg/3.0mm | |

ELECTRIC PROPERTIES | CONDUCTIVE TILE | DISSIPATIVE TILE |

10^4~10^6 ohm | 10^6~10^9 ohm | |

DECAY TIME | EQUAL 0.4S | EQUAL 0.4S |

CHARGE VOLTAGE | EQUAL 70 | EQUAL 70 |

FIRE RESISTANCE | B1 | B1 |

COMBUSTION PROPERTIES | EQUAL 0.35s|FV-0 | EQUAL 0.35s|FV-0 |

AMOUNT OF ANTI-WEAR | EQUAL 0.014 | EQUAL 0.014 |

ANTI-WEAR PROPERTIES | ITEN-T<2.0mm3 | ITEN-T<2.0mm3 |

WHEEL PRESSURE | No influence | No influence |

RESIDUAL CONCAVITY | 0.03mm(2.0 mm) | 0.03 mm(2.0 mm) |

DIMENSIONAL STABILITY EN434 | ≤0.10% | |

COLOR FASTNESS ISO105BO2 | At least 6 | At least 6 |

RESISTANCE TO CHENMICALS DIN423/DIN51958 | Offers excellent | Offers excellent resistance ask for special sheet |

IMPACT SOUND ABSORPTION VLI,ISO104,ISO717 | Approx 2dB | Approx 2dB |

STANDARD FOR HEALTH CARE FACILITIES NFPA 99 | Confirms to the requirement | |

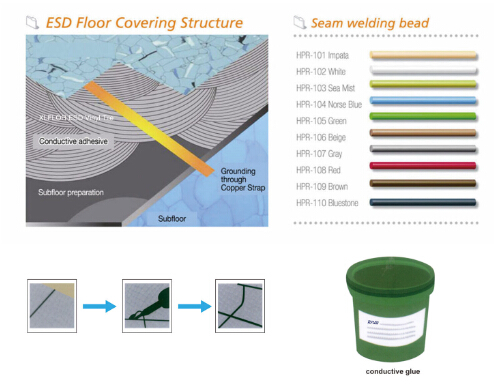

PVC installation guide

1 Materials include:

Dissipative PVC tile

Conductive adhesive

Welding rod

Copper foil

2 Main tools include:

Grooving machine, plastic welder, rubber hammer, cutting-off tool, ruler, brush, waxing machine, etc.

3 Ground requirements

The basic ground should be clean, dry and flat.

The foundation should be cement or terrazzo ground, but couldn’t have the phenomenon of sanding and separation. The strength of surface cement can’t be lower than No.75.

The ground should be flat, the unevenness must be less than 2/2000mm or make self-leveling cement ground.

If the foundation is formation, the ground must do waterproofing.

4 Note of installation

At installation, the ground residual moisture should not exceed 2.5% (CMDUMB test). The PVC floor, adhesive and job site’s temperature must keep above 18 degrees Celsius in 24 hours before the installation. High quality conductive adhesive and copper foil must be used in the installation.

5 PVC installation

Observe the layout of room, delimit datum line.

Lay copper foil. The intersection of the copper foil should be the center of PVC tile. The copper foil should be straight, not curly, not discontinuous. Make sure there’s long enough copper foil connected to the grounding terminal.

Brush conductive adhesive to the ground and copper foil. Uniform, overall, let it natural air-dry

Lay PVC tile efficiently when adhesive turn dry and not sticky to hand. The edges of the PVC should align with the datum line. Leave a bit gap about 1~2mm between tiles, but the width should be same. Tap the tiles with rubber hammer. Ensure tiles glued firmly. If the place is less than the length of the tile, precisely measure the size of floor, then cut and places it.

After laying all the PVC tiles, use grooving machine to open welding slot along with the gap. Slot line should be smooth and uniform. Generally, width 3±0.2mm is better.

Welding the slot for elegant appearance

After installation, clean the PVC floor.

|